PVC Wood Plastic Composite Door-panel Production Line

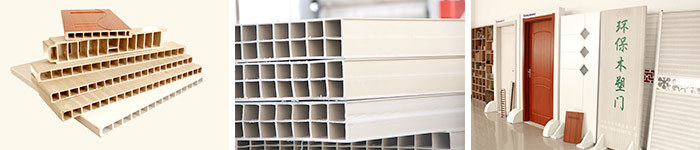

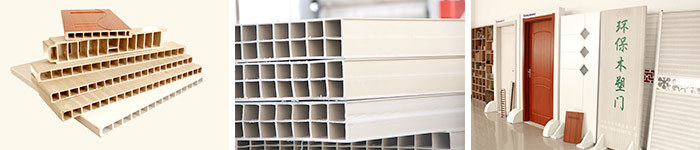

This production line is designed according to international latest technology, mixed PVC with plant fibre symmetrically. It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form. The wood plastic panel out from our line has features of green environment protection, damp proof, antisepticise and not distortion, thus suitable for processing method of wood and can be recycled to reuse. It has been widely used in wide door, partition panel, construction template, base plate of container, furnish panel, etc.

CONTACT US- Product Description

- 详细参数

- 产品说明

- 产品应用

-

- 商品名称: PVC Wood Plastic Composite Door-panel Production Line

This production line is designed according to international latest technology, mixed PVC with plant fibre symmetrically. It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form. The wood plastic panel out from our line has features of green environment protection, damp proof, antisepticise and not distortion, thus suitable for processing method of wood and can be recycled to reuse. It has been widely used in wide door, partition panel, construction template, base plate of container, furnish panel, etc.

This production line is designed according to international latest technology, mixed PVC with plant fibre symmetrically. It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form. The wood plastic panel out from our line has features of green environment protection, damp proof, antisepticise and not distortion, thus suitable for processing method of wood and can be recycled to reuse. It has been widely used in wide door, partition panel, construction template, base plate of container, furnish panel, etc.

Main Technical Specification

Model

TJ-MSB80/156

TJ-MSB92/188

Screw dia.

mm

Φ80/Φ156

Φ92/Φ188

Screw quantity

piece

2

2

Screw speed

r/min

1-38

1-32.9

Main extruder power

KW

55

110

Heating power (approx)

KW

36

45

Extrusion output

kg/h

200-400

300-550

Main Technical Specification of Auxiliary Machine

Model

BF800

BF1000

Max. product width

mm

800

1000

Draw-off height

mm

150

150

Draw-off force

KN

50

50

Draw-off speed

m/min

0-3

0-2.5

Total power of auxiliary machine

KW

35

40

Cooling water consumption

m3/h

9

12

Compressed air pressure

Mpa

0.6

0.6

Widely used in wide door panels, partition wall panels, building formwork, container floor, home decoration door and other fields.

-

主要技术参数

型号

JG-MSB80/156

JG-MSX92/188

螺杆直径

mm

Φ80/156

Φ92/188

螺杆数量

根

2

2

转速

r/min

1-38

1-32.9

主机功率

KW

55

110

加热功率(约)

KW

36

45

挤出产量

kg/h

200-400

300-550

辅机主要技术参数型号

BF800

BF1000

制品尺寸

mm

800

1000

牵引高度

mm

150

150

牵引力

KN

50

50

牵引速度

m/s

0-3

0-2.5

辅机总功率

KW

35

40

冷却水容量

m3/h

9

12

压缩空气压力

Mpa

0.6

0.6

-

-

广泛应用于宽幅门板、隔墙板、建筑模板、集装箱底板、家装套装门等领域。

Wechat QR code

Shandong Tongjia Machinery Co., Ltd.

Address: No. 96, 327 National Road, National High-tech Industrial Development Zone, Jining City, Shandong Province

Tel: +86-13792366525

+86-537-2279166 2986611 2986622

Fax: +86-537-2986199 2984888

Post Code: 272000

E-mail: sales@tongjia.com

sales@tongjia.com

sales@tongjia.com