XPE/IXPE Chemical Cross-link PE Foamed Sheet Production Line

XPE, or chemically cross-linked polyethylene foam material, is made of low-density polyethylene resin, cross-linking agent and foaming agent through high-temperature continuous foaming. Compared with other foaming materials, it has higher tensile strength and finer pores. IXPE, or radiation-cross-linked polyethylene foam, is made of polyethylene as the main raw material, mixed with foaming agent and other additives to form a master sheet, which is irradiated by high-energy electron beams generated by industrial electron accelerators to produce cross-linking (therefore different from traditional chemical cross-linking) to change the molecular structure of polyethylene into a tight three-dimensional network structure. After a series of processing steps such as free foaming, shaping, cooling and winding, an environmentally friendly closed-cell foam material is produced.

CONTACT US- Product Description

-

- 商品名称: XPE/IXPE Chemical Cross-link PE Foamed Sheet Production Line

XPE, or chemically cross-linked polyethylene foam material, is made of low-density polyethylene resin, cross-linking agent and foaming agent through high-temperature continuous foaming. Compared with other foaming materials, it has higher tensile strength and finer pores. IXPE, or radiation-cross-linked polyethylene foam, is made of polyethylene as the main raw material, mixed with foaming agent and other additives to form a master sheet, which is irradiated by high-energy electron beams generated by industrial electron accelerators to produce cross-linking (therefore different from traditional chemical cross-linking) to change the molecular structure of polyethylene into a tight three-dimensional network structure. After a series of processing steps such as free foaming, shaping, cooling and winding, an environmentally friendly closed-cell foam material is produced.

XPE or chemically cross-linked polyethylene foam material, is made of low-density polyethylene resin, cross-linking agent and foaming agent through high-temperature continuous foaming. Compared with other foaming materials, it has higher tensile strength and finer pores. IXPE, or radiation-cross-linked polyethylene foam, is made of polyethylene as the main raw material, mixed with foaming agent and other additives to form a master sheet, which is irradiated by high-energy electron beams generated by industrial electron accelerators to produce cross-linking (therefore different from traditional chemical cross-linking) to change the molecular structure of polyethylene into a tight three-dimensional network structure. After a series of processing steps such as free foaming, shaping, cooling and winding, an environmentally friendly closed-cell foam material is produced.

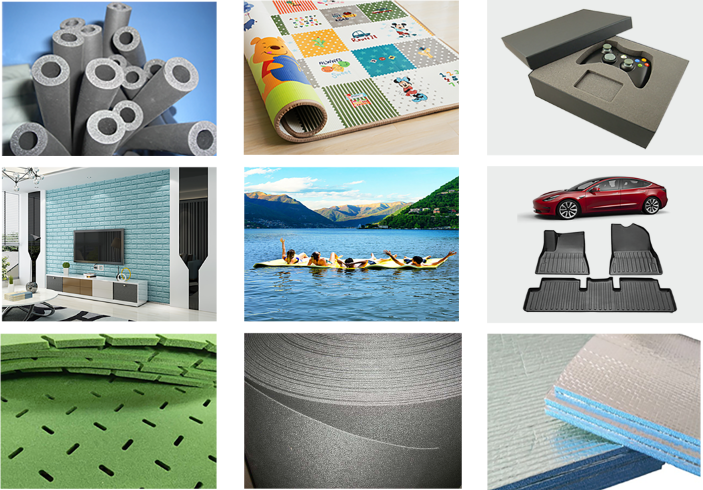

XPE/IXPE foam products are recognized as environmentally friendly materials in the world because the main gas contained in the material is nitrogen, which is non-toxic to the human body and non-polluting to the atmosphere. The internal structure is a uniformly distributed closed-cell structure, which is an ideal material for automobile and air conditioning insulation. In recent years, it has developed rapidly in the sports and leisure products market, such as surfboards, moisture-proof mats, yoga mats, etc. It also has certain uses in construction and has a wider application in flame retardant materials.

Granulating unit

Banburying machine

Model TJ-ZL-35L-120×15

TJ-ZL-55L-135×15

TJ-ZL-75L-150×15

Capacity L

35

55

75

The main motor power KW

55

75

110

Output(approx) Kg/h

150-220

220-300

220-300

Dimensions (L×W×H)(approx) m

2.3×1.4×2.8

2.5×1.6×3.0

2.5×1.8×3.2

Pelletizer machine

Screw Ø120x15

Ø135x15

Ø150x15

The main motor power KW

45

55

75

Output(approx) Kg/h

150-220

220-300

220-300

Dimensions (L×W×H)(approx) m

3.5×2.4×1.4

3.6×2.7×1.6

3.8×3.0×1.8

Sheet unit

Model TJ-ZP-150×28

TJ-ZP-160×28

TJ-ZP-170×28

Extruder Ø150/28

Ø160/28

Ø170/28

The main motor power KW

132

132

160

Output(approx) Kg/h

140-160

160-180

180-200

Dimensions (L×W×H)(approx) m

11×3.0×2.8

12×3.2×3.0

13×3.4×3.2

Horizontal foaming unit

Model TJ-P-FP-22x1.5

TJ-P-FP-22x1.8

TJ-P-FP-22x2.0

Oven shell dimensions(L×W) m

22x2.7x5

22x2.5x5.2

22x2.7x5.4

Heat Kcal/h

220000

240000

250000

Power KW

50

55

60

Max.output(approx) Kg/h

120-180

160-200

180-240

Thickness of product mm

3-15

3-15

3-15

Width of product mm

600-1500

600-1800

600-2000

Vertical foaming unit

Model TJ-CZFP-(8+4)x1.2

TJ-CZFP-(8+4)x1.5

TJ-CZFP-(8+4)x1.8

Oven shell dimensions(L×W) m

8x1.2+4x1.8

8x1.5+4x2.0

8x1.8+4x2.3

Power KW

160+11

180+11

200+11

Max.output(approx) Kg/h

60-90

80-120

100-150

Thickness of product mm

0.5-5

0.5-5

0.5-5

Width of product mm

600-1200

700-1500

800-1800

Application

① Construction: thermal insulation, sound insulation, and moisture insulation for roofs, floors, and interior walls of residential buildings, office buildings, especially foreign-related luxury hotels and hotels; thermal insulation for oil storage tanks, cold storage, central air conditioners, and pipeline facilities; thermal insulation for vegetable greenhouses.

② Transportation: moisture-proof and antifreeze layers for roadbeds in cold areas; thermal insulation for vehicles, ships, and aerospace engineering.

③ Sports and fitness: safety protection layers for kindergartens and medical protective equipment; high-end children's crawling mats, yoga mats, puzzle boards, wrestling mats, military camping mats, and camping tents.

④ Packaging: precision measuring tools, cutting tools, and electronic products; packaging materials for high-end foods, health products, and cosmetics, etc.

Wechat QR code

Shandong Tongjia Machinery Co., Ltd.

Address: No. 96, 327 National Road, National High-tech Industrial Development Zone, Jining City, Shandong Province

Tel: +86-13792366525

+86-537-2279166 2986611 2986622

Fax: +86-537-2986199 2984888

Post Code: 272000

E-mail: sales@tongjia.com

sales@tongjia.com

sales@tongjia.com