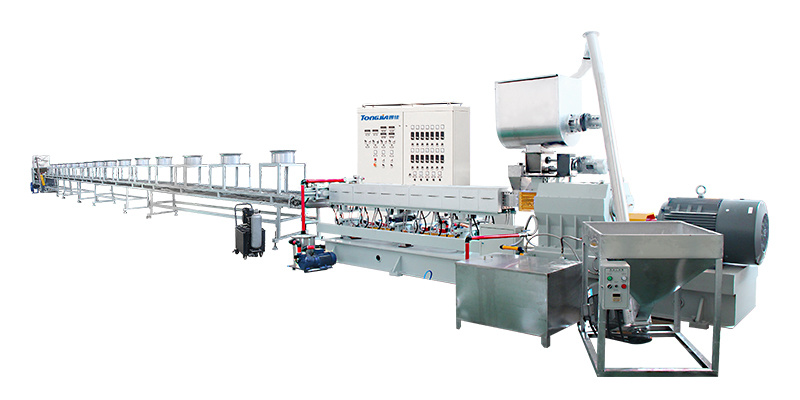

Bio-based biodegradable material modification granulator

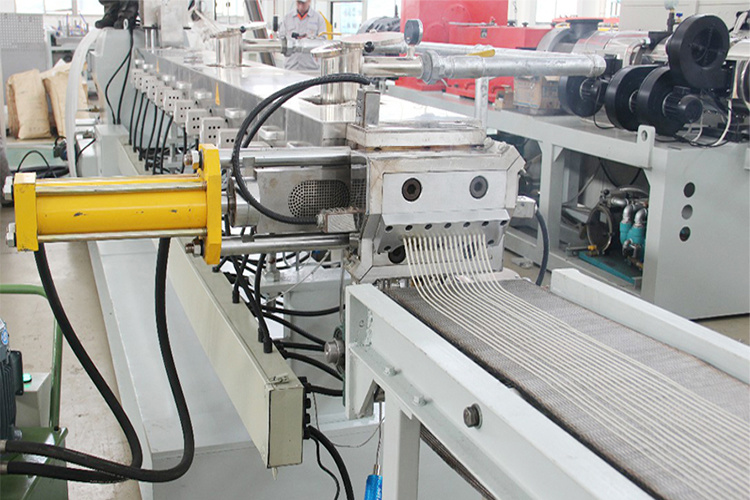

The building block screw element, the screw configuration is precisely designed by computer, the aspect ratio is increased, the structure can be changed and adjusted according to the process requirements, and the configuration is optimized. The screw element and the mandrel are connected by involute spline to achieve higher torque and larger screw volume. The screw element is made of high-quality alloy steel W6Mo5CrlV2, the mandrel is made of 40CrNiMoA, and the double alloy bushing inside the barrel can be used for a variety of operations. The vacuum exhaust barrel allows the moisture in the material to fully evaporate and reduce the moisture content of the particles.

CONTACT US- Product Description

- 详细参数

- 产品说明

- 产品应用

-

- 商品名称: Bio-based biodegradable material modification granulator

The building block screw element, the screw configuration is precisely designed by computer, the aspect ratio is increased, the structure can be changed and adjusted according to the process requirements, and the configuration is optimized. The screw element and the mandrel are connected by involute spline to achieve higher torque and larger screw volume. The screw element is made of high-quality alloy steel W6Mo5CrlV2, the mandrel is made of 40CrNiMoA, and the double alloy bushing inside the barrel can be used for a variety of operations. The vacuum exhaust barrel allows the moisture in the material to fully evaporate and reduce the moisture content of the particles.

The building block screw element, the screw configuration is precisely designed by computer, the aspect ratio is increased, the structure can be changed and adjusted according to the process requirements, and the configuration is optimized. The screw element and the mandrel are connected by involute spline to achieve higher torque and larger screw volume. The screw element is made of high-quality alloy steel W6Mo5CrlV2, the mandrel is made of 40CrNiMoA, and the double alloy bushing inside the barrel can be used for a variety of operations. The vacuum exhaust barrel allows the moisture in the material to fully evaporate and reduce the moisture content of the particles.

Model TJ-ZL75P

TJ-ZL95P

Screw diameter mm

Ø75×2

Ø95×2

Number of screws piece

2

2

Speed r/min

1-500

1-500

Main motor power KW

132/160

280

Cooling method Cooled by wind

Screw ratio 48:1 / 52:1

48:1 / 52:1

Heating power (approx.) KW

80

150

Extrusion output kg/h

300-600

500-800

Machine details

Application

-

Wechat QR code

Shandong Tongjia Machinery Co., Ltd.

Address: No. 96, 327 National Road, National High-tech Industrial Development Zone, Jining City, Shandong Province

Tel: +86-13792366525

+86-537-2279166 2986611 2986622

Fax: +86-537-2986199 2984888

Post Code: 272000

E-mail: sales@tongjia.com

sales@tongjia.com

sales@tongjia.com