Photovoltaic Module Frame Pultrusion ProductionLline

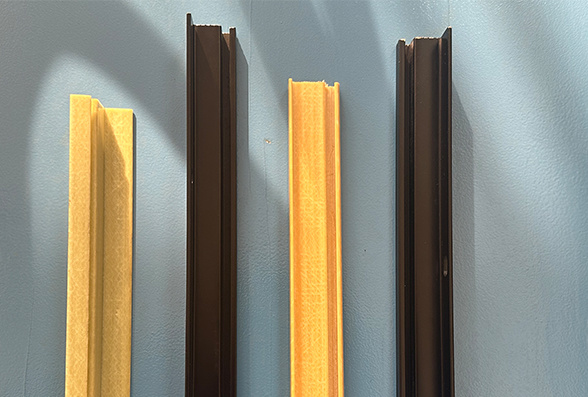

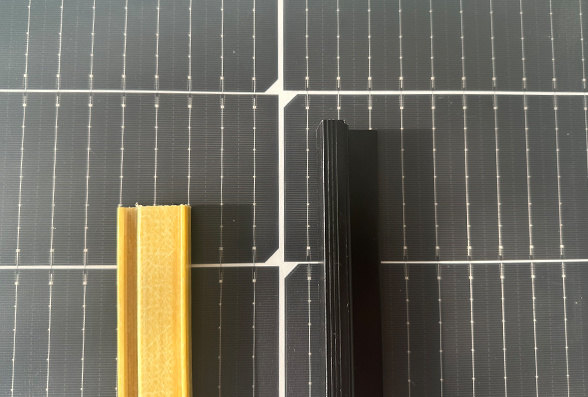

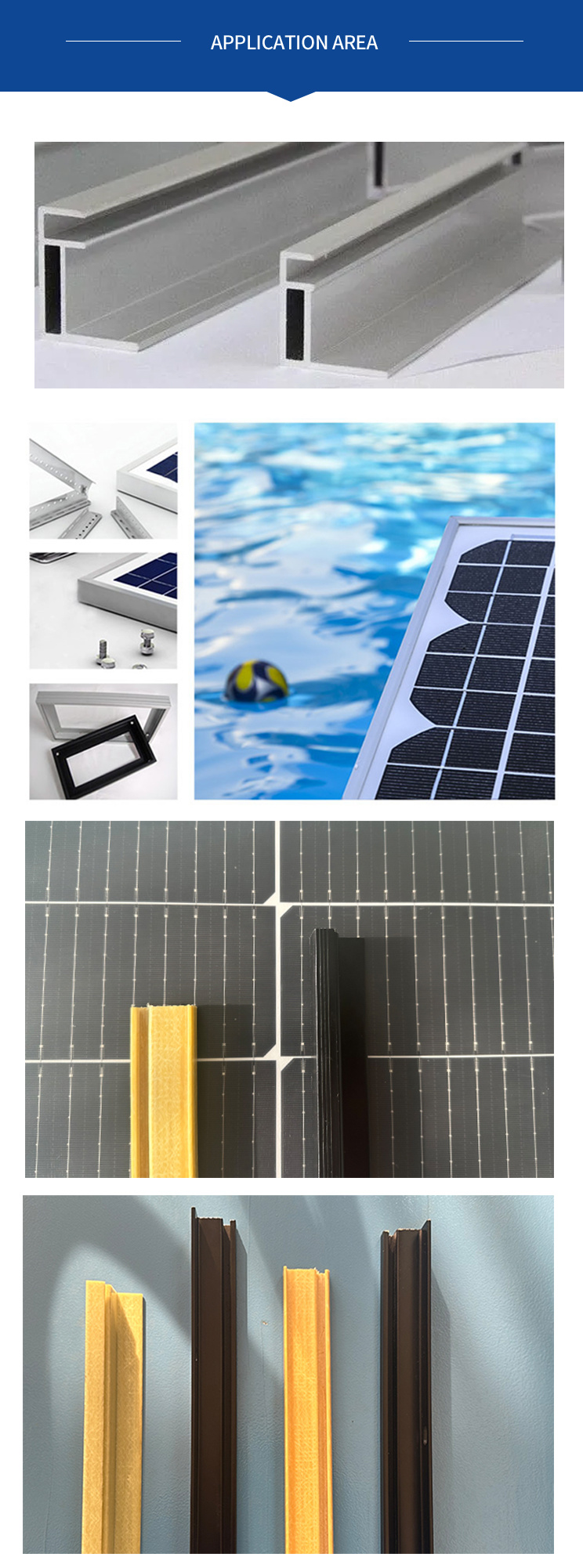

Polyurethane pultruded composite materials are used in photovoltaic module frames. Compared with aluminum frames, composite frames have advantages in many aspects: excellent mechanical properties, excellent corrosion resistance, thermal expansion coefficient comparable to glass, which is beneficial to the long-term performance of module packaging, lower cost than aluminum alloy frames, and grounding-free is possible, further reducing costs. This equipment uses interactive HIMI touch screen control. The pultrusion speed, temperature, and clamping force are all displayed and controlled on the touch screen. Two products are made at a time. It has automatic alarms for oil temperature and oil filter blockage, and stepless adjustment of traction speed. The main electrical and hydraulic components are internationally renowned brands with high sensitivity and low failure rate. It uses pneumatic up and down cutting, pneumatic pressing, and pneumatic tracking. The cutting saw blade is a toothless saw blade.

CONTACT US- Product Description

-

- 商品名称: Photovoltaic Module Frame Pultrusion ProductionLline

Polyurethane pultruded composite materials are used in photovoltaic module frames. Compared with aluminum frames, composite frames have advantages in many aspects: excellent mechanical properties, excellent corrosion resistance, thermal expansion coefficient comparable to glass, which is beneficial to the long-term performance of module packaging, lower cost than aluminum alloy frames, and grounding-free is possible, further reducing costs. This equipment uses interactive HIMI touch screen control. The pultrusion speed, temperature, and clamping force are all displayed and controlled on the touch screen. Two products are made at a time. It has automatic alarms for oil temperature and oil filter blockage, and stepless adjustment of traction speed. The main electrical and hydraulic components are internationally renowned brands with high sensitivity and low failure rate. It uses pneumatic up and down cutting, pneumatic pressing, and pneumatic tracking. The cutting saw blade is a toothless saw blade.

Polyurethane pultruded composite materials are used in photovoltaic module frames. Compared with aluminum frames, composite frames have advantages in many aspects: excellent mechanical properties, excellent corrosion resistance, thermal expansion coefficient comparable to glass, which is beneficial to the long-term performance of module packaging, lower cost than aluminum alloy frames, and grounding-free is possible, further reducing costs. This equipment uses interactive HIMI touch screen control. The pultrusion speed, temperature, and clamping force are all displayed and controlled on the touch screen. Two products are made at a time. It has automatic alarms for oil temperature and oil filter blockage, and stepless adjustment of traction speed. The main electrical and hydraulic components are internationally renowned brands with high sensitivity and low failure rate. It uses pneumatic up and down cutting, pneumatic pressing, and pneumatic tracking. The cutting saw blade is a toothless saw blade.

Model TJ-LJ100

TJ-LJ200

TJ-LJ300

TJ-LJ400

TJ-LJ500

TJ-LJ800

Maximum traction KN

100

200

300

400

500

800

Maximum holding force KN

100

200

300

400

500

800

Traction speed m/min

0.1-1.0

0.1-1.0

0.1-1.0

0.1-0.7

0.1-0.5

0.1-0.36

Hydraulic system power KW

2x4

2x5.5

2x7.5

2x5.5

2x5.5

2x7.5

Clamping space mm

600x400

800x300

800x300

800x300

1000x300

1500x400

Hydraulic Mpa

2-16

Air pressure Mpa

0.4-0.6

Control method PLC

◆Adopt interactive HIMI touch screen control, the pultrusion speed, temperature, and clamping force are all displayed and controlled on the touch screen. Two products are made at a time, and each mold is controlled separately;

◆The hydraulic cylinder seals are imported, and the pump group has stable power output;

◆With automatic alarm for oil temperature and oil filter blockage, and stepless adjustment of traction speed;

◆The main electrical and hydraulic components are internationally renowned brands, with high sensitivity and low failure rate;

◆Adopt pneumatic up and down cutting, pneumatic pressing, pneumatic tracking, and the cutting saw blade is a toothless saw blade

Wechat QR code

Shandong Tongjia Machinery Co., Ltd.

Address: No. 96, 327 National Road, National High-tech Industrial Development Zone, Jining City, Shandong Province

Tel: +86-13792366525

+86-537-2279166 2986611 2986622

Fax: +86-537-2986199 2984888

Post Code: 272000

E-mail: sales@tongjia.com

sales@tongjia.com

sales@tongjia.com