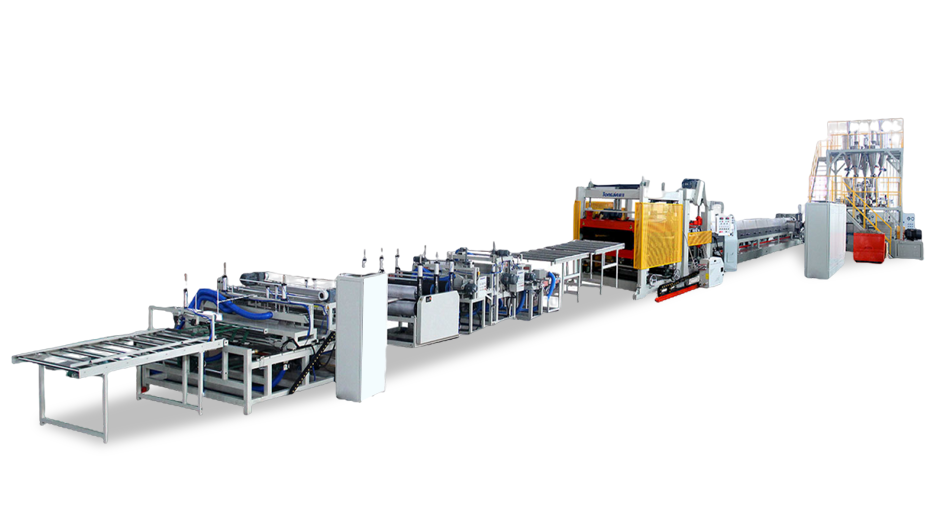

TJ-HB30L-120L Blow Molding Machine

- Commodity name: TJ-HB30L-120L Blow Molding Machine

Subcategory

Contact information

keyword

Product details

Tongjia TJ-HBD30L-160L Series Double-Station Blow Molding Machine is a customizable solution designed to meet the diverse needs of our customers. This high-output machine is primarily used for producing a wide range of hollow products such as chemical barrels, civilian barrels, medical packaging, and road barriers. The machine can be easily adjusted by changing parts to accommodate different customer requirements.

Key Features:

- ◆ Double-station blow molding machine for higher productivity

- ◆ Customizable to meet various production needs, including chemical barrels, road barriers, and medical packaging

- ◆ Higher output: Produces twice the output of a single-station machine

- ◆ Imported PLC control system with European machine control technology

- ◆ Fully imported hydraulic valves and servo control system for enhanced precision and performance

This double-station blow molding machine is ideal for customers requiring high output and flexibility in production, providing advanced control systems and efficient manufacturing for large-scale production.

| Configuration | ||||||

| Clamping system | Diagonal double tie bar center clamping bi-directional synchronous high precision linear guideway clamping device | |||||

| Extrusion system | Hardened face gear reducer + Imported frequency inverter | |||||

| Diesystem | Special steel center-feeding die | |||||

| Hydraulic system | All imported hydraulic valve + hydraulic servo control system | |||||

| Control system | Imported PLC + Europe imported complete machine control system (GEFRAN from Italy) | |||||

| Parameters | ||||||

| Specifications | Units | TJ-HB30L | TJ-HB60L | TJ-HB80L | TJ-HB100L | TJ-HB120L |

| Material | PE.PP.ABS … | PE.PP.ABS … | PE.PP.ABS … | PE.PP.ABS … | PE.PP.ABS … | |

| Max.product capacity | L | 30 | 60 | 80 | 100 | 120 |

| Die quantity | Set | 1 | 1 | 1 | 1 | 1 |

| Machine dimension | M | 4.85X3.5X3.7 | 4.9X3.5X4.0 | 4.9X3.5X4.3 | 5.7X3.9X4.5 | 5.7X3.9X4.5 |

| Machine weight | Ton | 10 | 13 | 14 | 16 | 17 |

| Die-head | ||||||

| Accumulatorcapacity | L | 4.4 | 6.6/8.8 | 6.6/8.8 | 12.8/13.8 | 12.8/13.8 |

| Max.diameter of die | mm | 200 | 300 | 300 | 400 | 400 |

| Die head heating power | KW | 21 | 26 | 26 | 33/38.6 | 33/38.6 |

| Die head heating zone quantity | zone | 3 | 3 | 3 | 3 | 3 |

| Clamping Unit | ||||||

| Clamping force | KN | 300 | 380 | 380 | 450 | 450 |

| Distance between platens | mm | 400-900 | 450-1000 | 450-1000 | 500-1200 | 500-1200 |

| Mold platen size (W x H) | mm | 780X700 | 885X780 | 885X1000 | 1060X1060 | 1060X1230 |

| Extruder unit | ||||||

| Screw diameter | mm | 80 | 90 | 90 | 100 | 200 |

| Screw L/D ratio | L/D | 25 | 25 | 25 | 25 | 25 |

| HDPE Plasticizing amount | Kg/h | 110 | 130/160 | 130/160 | 160/200 | 160/200 |

| Screw heating zone quantity | zone | 5 | 5 | 5 | 5 | 5 |

| Screw heating power | KW | 16 | 20 | 20 | 23 | 23 |

| Extruder driving power | KW | 30 | 37/45 | 37/45 | 45/55 | 45/55 |

| Power | ||||||

| Total power consumption | KW | 91 | 120/128 | 120/128 | 138/154 | 138/154 |

| Hydraulic drive power | KW | 24 | 37 | 37 | 37 | 37 |

| Cooling water consumption | m3/h | 3.6 | 5 | 5 | 6 | 6 |

| Cooling water pressure | Mpa | 0 3-0.6 | 0.3-0.6 | 0 3-0.6 | 0 3-0.6 | 0 3-0.6 |

| Air pressure | Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Air consumption | m3/min | 0.8 | 1 | 1 | 1.2 | 1.2 |

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.