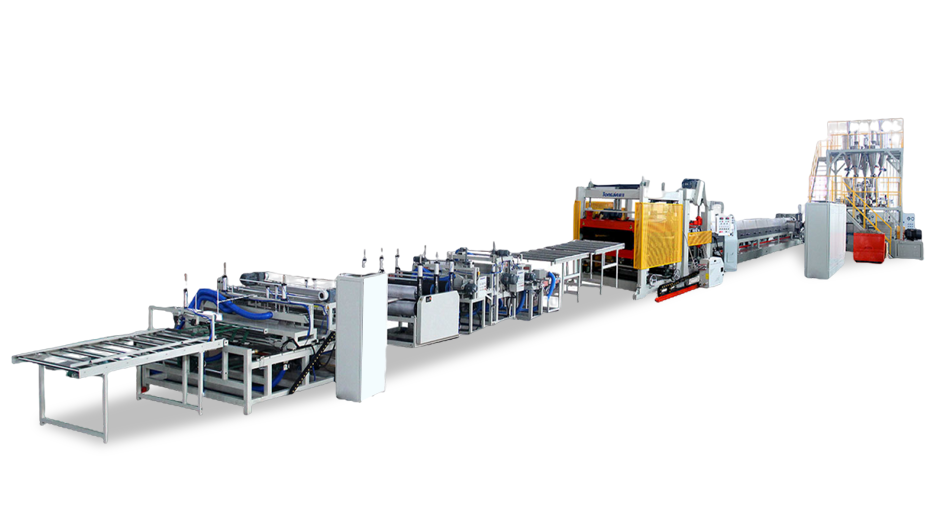

Ecomomy CO2 XPS Foamed Board Production Line

- Commodity name: Ecomomy CO2 XPS Foamed Board Production Line

Subcategory

Contact information

keyword

Product details

The XPS production line manufactures thermal insulation boards from polystyrene and a foaming agent through high-temperature extrusion. Traditionally, HCFC foaming agents were used, but due to their ozone-depleting potential, their use is being gradually restricted under the Montreal Protocol.

In response, Shandong Tongjia Machinery Co., Ltd. has developed CO2-based extruded board equipment, replacing HCFC with CO2. This fully fluorine-free foaming process sets a new standard for eco-friendly XPS production.

| Model |

|

TJ-XPS75P/150 |

TJ-XPS75P/170 |

TJ-XPS75P/200 |

|||

| Extruder |

|

Ø75 |

Ø150 |

Ø75 |

Ø170 |

Ø75 |

Ø200 |

| Heating power (approx) |

KW |

60 |

65 |

60 |

80 |

75 |

100 |

| Thickness of board |

mm |

20-100 |

20-110 |

20-120 |

|||

| Width of board |

mm |

600,900,1220 |

600,900,1220 |

600,900,1220 |

|||

| Output (approx) |

kg/h |

400-500 |

500-600 |

550-700 |

|||

| Installed capacity (approx) |

KW |

290 |

320 |

400 |

|||

| Dimensions(L×W×H)(approx) |

m |

50×10×4 |

55×10×4 |

70×12×4 |

|||

| Total weight(approx) |

T |

28 |

30 |

33 |

|||

Multi-Component Mixing System

Fully automated computer control for accurate raw material ratio and precise weightless metering, ensuring high-quality production. Vacuum feeding system guarantees stable material delivery.

Cooling and Constant Temperature System

High-power chiller with precise temperature control for effective cooling and stable production, ensuring high-quality XPS foam boards.

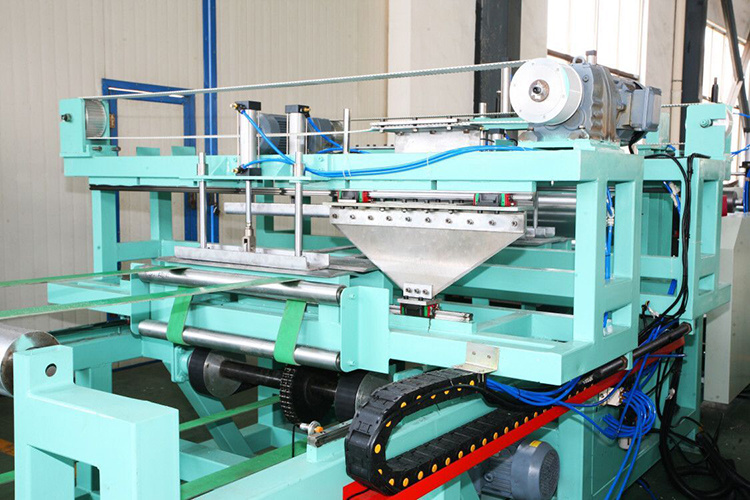

Extrusion System

Parallel twin-screw extruder with a screw building block structure for efficient material mixing, uniform dispersion, and high-quality XPS foam board production.

CO2 Foaming Agent Injection System

Patented supercritical CO2 foaming system with advanced flow control technology ensures homogeneous foam products, stable CO2 liquid phase, and precise foaming agent control.

Conveying System

Electric adjustable device for low resistance material handling and double-sided shaping, optimizing XPS foam board formation.

Fixed-Length Cutting System

Automatic cutting, trimming, shaping, and stacking, with multi-point monitoring and automatic packaging, enhancing production efficiency and automation.

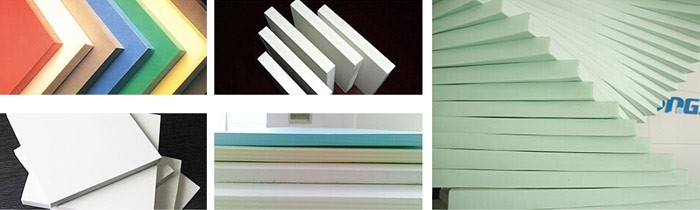

Application:

XPS Physical Foamed Board (Extrusion Polystyrene Foam) is a highly efficient thermal insulation material with a closed-pore alveolate structure. It offers superior properties including low density, minimal water absorption, excellent heat insulation, and vapor permeability. XPS is known for its high strength, light weight, airtightness, corrosion resistance, aging resistance, and cost-effectiveness.

Applications of XPS Board:

◆ Construction Industry: Waterproofing, heat insulation, and thermal preservation for walls and roofs of residential, office, and industrial buildings.

◆ Refrigeration: Cold storage and insulation for refrigeration warehouses.

◆ HVAC: Heat insulation and preservation for central air conditioning ventilation pipes.

◆ Water Conservancy: Anti-freezing material for concrete water delivery systems, including large-scale water diversion projects.

Transportation Infrastructure: Heat preservation and anti-freezing for roadbed projects in highways, railways, airports, and squares.

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.