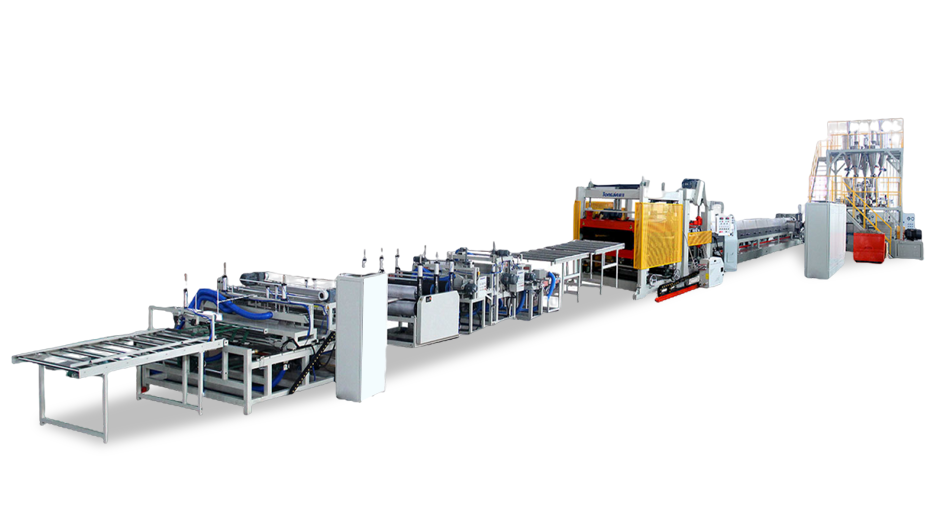

Fully automatic new EVA solar film machine(Roller type)

- Commodity name: Fully automatic new EVA solar film machine(Roller type)

Subcategory

Contact information

keyword

Product details

The automated EVA solar film production line is designed for high-efficiency production, low manual intervention, and real-time monitoring. This system boosts production efficiency, reduces costs, and delivers high-quality solar films.

Key Features:

◆ Full Automation: From EVA pretreatment to cutting and collection, the production process is fully automated, improving reliability and speed.

◆ Minimal Human Intervention: Reduces operator involvement, minimizing human error and enhancing production stability.

◆ Real-Time Monitoring: Equipped with sensors to ensure accuracy and consistency at every stage of production.

◆ Precision Cutting: High-precision cutting and automatic control systems ensure uniformity and quality in each batch.

◆ Eco-Friendly: Uses high-quality, environmentally friendly materials for pollution-free solar panel films.

| Model |

| TJ-160 | TJ-180 | TJ-150 | TJ-90 | TJ-120 |

| Raw Materials |

| EVA/POE | EVA/POE | PVB/SGP | TPU | TPU |

| Product thickness | mm | 0.2-1.0 | 0.2-1.0 | 0.35-2.26 | 0.35-2.0 | 0.35-2.0 |

| Product width | mm | 2200 | 2600 | 2600 | 1600 | 2000 |

| Extrusion volume (approx.) | kg/h | 600 | 800 | 400 | 220 | 400 |

| Line speed | m/min | 10 | 10 | 9 | 6 | 6 |

◆ Efficient and low-cost production with automated control

◆ Enhanced production stability and reduced human intervention

◆ High-precision cutting for perfect solar film performance

◆ Environmentally friendly production, reducing environmental impact

Ideal for manufacturers aiming to produce high-quality solar panels at scale with reduced operational costs.

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.