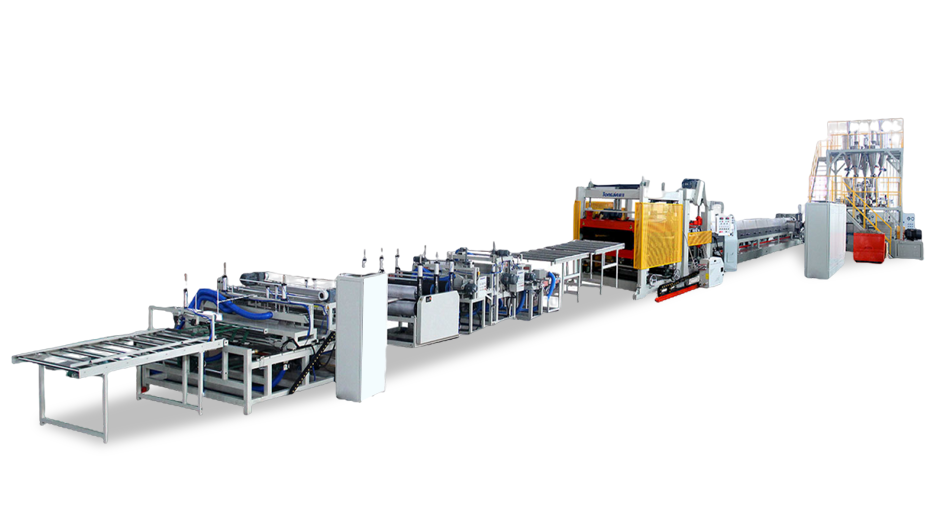

Plastic Crate Special Injection Molding Machine

- Commodity name: Plastic Crate Special Injection Molding Machine

Subcategory

Contact information

keyword

Product details

Tongjia Plastic crate injection molding machine features:

Tongjia Plastic crate injection molding machine combines the most advanced concept of foreign plastic machine, optimizes the parametersand configuration of injection molding machine, and achieves many excellent performances such as stability, fast and efficient, high precision and high response. This series of models has a short cycle, high production efficiency, and the screw is resistant to wear. According to the high cost performance, it is specially developed for the turnover basket.

Tongjia Plastic crate special injection molding machine has the following excellent features:

(1)With an optimized hydraulic system, the injection speed is greatly improved.

(2)Matching double alloy screw barrel, super wear-resistant, corrosion-resistant, greatly improving the service life of the machine.

(3) Directly drive the injection molding system with servo motors from well-known foreign brands to achieve high response and low noise.

(4)Low energy consumption, saving customers money and getting more profits.

| Model | Modle | Unit | TH460/3200 | TH520/3600 |

| Injection Unit | Screw diameter | mm | 90 | 95 |

| Screw L/D ratio | L/D | 18.3 | 18.5 | |

| Injection Weight | g | 2688.8 | 3071.7 | |

| Injection pressure | MPa | 128.3 | 135 | |

| Injection stroke | mm | 395 | 405 | |

| Clamping part | Clamping Force | KN | 4600 | 5200 |

| Clamping stroke | mm | 800 | 840 | |

| Space between tie-bars | mm | 780×780 | 820×820 | |

| Max. Mold Height | mm | 780 | 800 | |

| Min. Mold Height | mm | 300 | 320 |

The plastic turnover basket is also called the turnover basket. The plastic turnover box is mainly used for the storage and turnover of items. Anti-rat bite), safety (no nails, no radiation, non-toxic and tasteless), convenient (no repairs, easy to handle), pressure resistance and so on. The products are made of plastic resin raw materials or secondary materials (plastic recycling materials) by injection molding, and are divided into two types: high-density polyethylene (HDPE) and polypropylene (PP). It has been widely used in the international market, and it belongs to the sunrise industry in my country with a bright future. In fruit-producing areas, vegetable-producing areas, and aquaculture, a large number of entrepreneurs have invested in building factories, purchasing machines to produce turnover baskets, and harvesting commendable economic benefits.

Официальный дилер Tongjia в России:

Russia website: www.tongjiarus.ru

Russia Phone No.: +7 (347) 299-22-07

Russia Email: office@tongjiarus.ru

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.