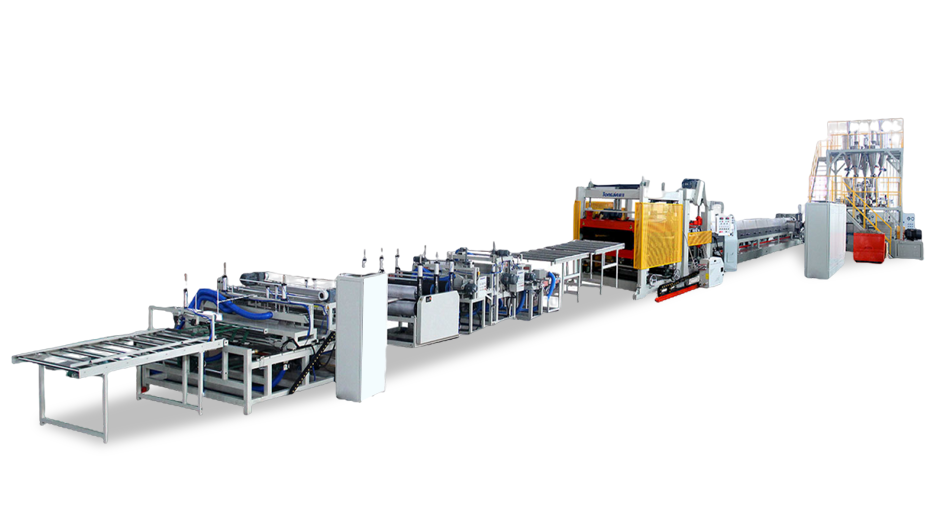

PET Bottle Preform Injection Molding Machine

- Commodity name: PET Bottle Preform Injection Molding Machine

Subcategory

Contact information

keyword

Product details

In order to meet the needs of the market, Tongjia Company creates a new profit space for customers, and a new high-efficiency and energy-saving injection molding machine for PET tube blanks.

PET Bottle Preform Injection Molding Machine main features:

○ Special structural design to facilitate the plastic molding of PET raw materials.

○ Injection line clamping and mold opening adopt line potentiometer, which can precisely control the stroke with a precision of up to 0.01mm.

○ The variable pump control system saves 25%-45% compared to conventional machines, and the servo control system saves 30%-50% compared to conventional machines.

○ PID temperature control, with screw cooling start limit, wire break detection, heat preservation and other functions, Small error in temperature control, which is favorable for molding stability.

○ Increase the ejection force and ejection stroke to meet the requirements for the ejection of preforms.

○ With mold needle valve control interface.

○ Optional synchronous pressure maintaining system can increase production capacity by 15%-25%.

○ Microcomputer controller 4 segments injection, 3 sections of pressure, 3 sections of back pressure, holding position switching control, 100 sets of mold data memory functions.

| Ltem | Model | Unit | TH220/PET | TH260/PET | TH320/PET | TH360/PET | TH460/PET |

| Injection Unit | Screw diameter | mm | 50.00 | 55.00 | 60.00 | 65.00 | 83.00 |

| Screw L/D ratio | L/D | 24.00 | 24.00 | 24.00 | 24.00 | 25.00 | |

| Theroy Injection Volume | cm3 | 441.79 | 605.84 | 783.20 | 995.49 | 2131.78 | |

| (PET)Injection weight | g | 605.25 | 830.00 | 1072.98 | 1363.82 | 2920.54 | |

| Injection pressure | MPa | 192.70 | 185.12 | 192.50 | 192.81 | 150.89 | |

| Injection rate into air | cm3/s | 193.74 | 252.08 | 303.03 | 378.18 | 579.88 | |

| Injection stroke | mm | 225.00 | 255.00 | 277.00 | 300.00 | 394.00 | |

| Injection speed | mm/s | 98.7 | 106.1 | 107.2 | 114 | 107.2 | |

| Maximum speed of screw | rpm | 163.68 | 163.10 | 181.16 | 192.16 | 186.04 | |

| Clamping Unit | Clamping force | KN | 2200 | 2600 | 3200 | 3600 | 4600 |

| Clamping stroke | mm | 540 | 550 | 650 | 690 | 800 | |

| Mould Platen Size | mm | 800x800 | 860x860 | 940x940 | 1005x1005 | 1155x1155 | |

| Space between tie-bars | mm | 530x530 | 580x580 | 630x630 | 680x680 | 780x780 | |

| Max.Mould height | mm | 560 | 600 | 650 | 700 | 780 | |

| Min.Mould height | mm | 220 | 250 | 250 | 280 | 300 | |

| Enject stroke | mm | 150 | 160 | 160 | 160 | 200 | |

| Hydraulic ejection | KN | 68 | 68 | 68 | 68 | 184 | |

| Q'ty of ejector rod | Piece | 9 | 9 | 13 | 13 | 17 | |

General |

Motor of pump | KW | 24 | 34 | 37 | 46 | 61 |

| Heat power | KW | 15 | 19 | 23 | 27 | 30 | |

| Volume of hopper | L | 50.00 | 50.00 | 50.00 | 50.00 | 50.00 | |

| Volume of oil pump | L | 400.00 | 550.00 | 700.00 | 750.00 | 850.00 | |

| Machine Weight(about) | T | 7.50 | 9.00 | 11.00 | 13.00 | 18.00 | |

| Mould positioning ring diameter | mm | 160 | 160 | 160 | 160 | 200 | |

| The sphere radius | mm | SR10 | SR10 | SR15 | SR15 | SR15 | |

| Dimensions(L*W*H) | m | 5.6x1.5x2.2 | 5.9x1.6x2.3 | 6.7x1.7x2.4 | 6.9x1.72x2.4 | 8.6x1.87x2.5 |

Официальный дилер Tongjia в России:

Russia website: www.tongjiarus.ru

Russia Phone No.: +7 (347) 299-22-07

Russia Email: office@tongjiarus.ru

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.