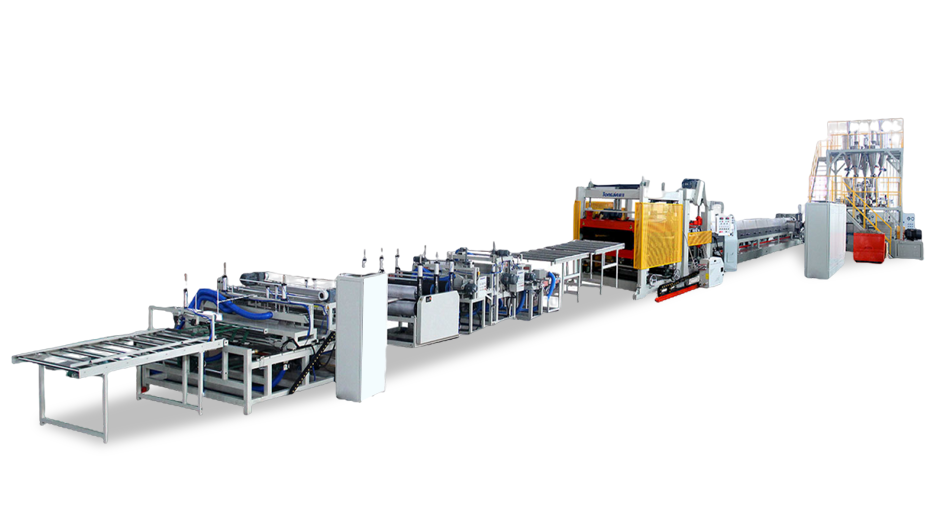

EPE Foamed Sheet/Film Production Line

- Commodity name: EPE Foamed Sheet/Film Production Line

Subcategory

Contact information

keyword

Product details

The Tongjia EPE Foam Film Production Line offers advanced technology for high-quality foam production with exceptional efficiency and flexibility.

Key Features:

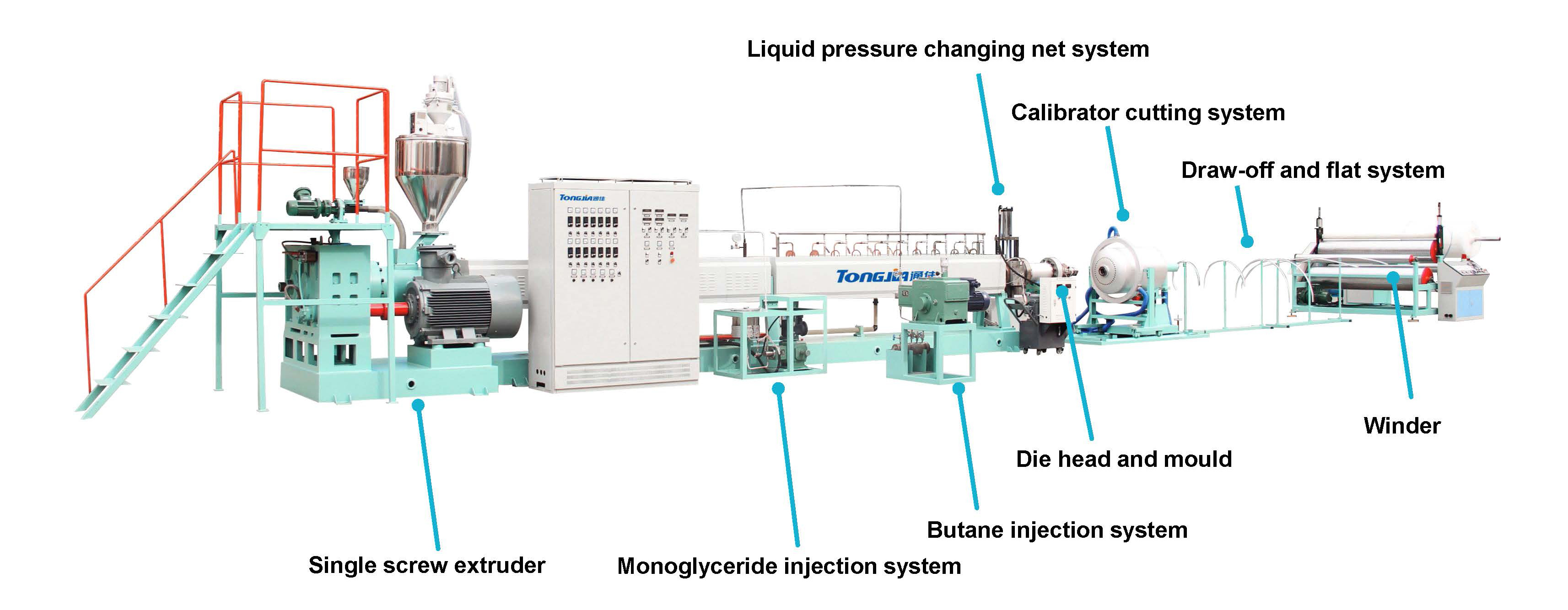

◆ Single-Machine Foaming Process: High foaming ratio, producing white, delicate foam films.

◆ Environmentally-Friendly Foaming Agent: Uses butane for superior quality and eco-friendly production.

◆ Energy-Saving & Stable Operation: Features explosion-proof motors, variable frequency speed control, and a reliable electrical control system.

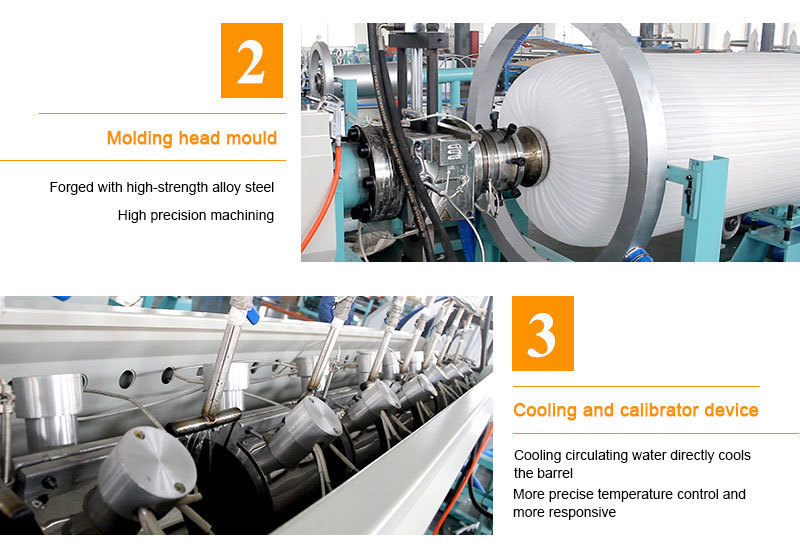

◆ Precise Temperature Control: Digital control with cooling circulating water for accurate and responsive temperature regulation.

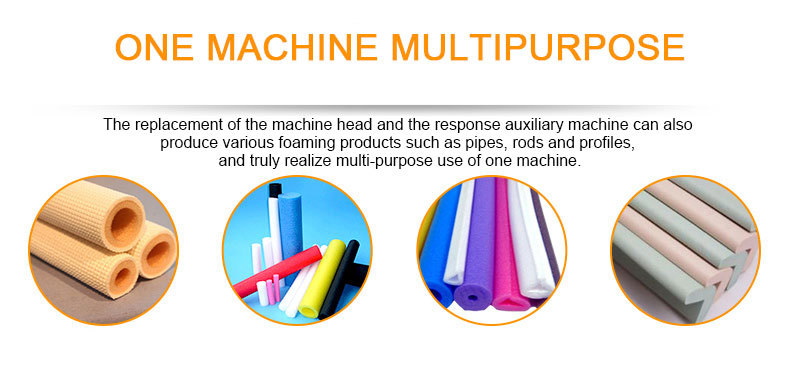

◆ Versatile Production Line: Capable of making foam tubes, foam rods, and more with easy machine head replacements.

Benefits:

◆ Efficient Production: High-quality foam production with reduced energy consumption.

◆ Eco-Friendly: Butane foaming agent reduces environmental impact.

◆ Cost-Effective & Flexible: Multi-purpose production line, providing maximum flexibility and cost-efficiency.

The Tongjia EPE Foam Film Production Line is ideal for manufacturers seeking energy-efficient, high-quality foam products with flexibility and cost-efficiency.

| Main Technical Specification | |||||

| Model | TJ-FPM90 | TJ-FPM105 | TJ-FPM120 | TJ-FPM135 | |

| Extruder | Φ90/55 | Φ105/55 | Φ120/55 | Φ135/55 | |

| Output (approx) | kg/h | 70-90 | 100-130 | 140-170 | 200-220 |

| Foam rate | times | 30-60 | 30-60 | 30-60 | 30-60 |

| Width of product | mm | 1000-1400 | 1000-1600 | 1000-1600 | 1000-1800 |

| Thickness of product | mm | 0.5-4.0 | 0.5-5.5 | 0.8-6.5 | 1.0-8.0 |

| Cooling method | Cooled by wind and water | ||||

| Installed capacity (approx) | KW | 85 | 90 | 115 | 155 |

| Dimensions (L×W×H)(approx) | m | 22x2.3x2.2 | 23x2.3x2.2 | 25x2.3x2.2 | 26x2.5x2.4 |

| Total weigh(approx) | T | 8.5 | 9 | 10 | 12 |

| Model | JG-FPM150 | JG-FPM180 | JG-FPM200 | JG-FPM250 | |

| Extruder | Φ150/55 | Φ180/55 | Φ200/55 | Φ250 | |

| Output (approx) | kg/h | 320-360 | 450-520 | 550-650 | 600-850 |

| Foam rate | times | 30-60 | 30-60 | 30-60 | 30-60 |

| Width of product | mm | 1000-2000 | 1000-3000 | 1000-3000 | 1000-3000 |

| Thickness of product | mm | 2.0-12.0 | 3.0-16.0 | 3.0-25.0 | 5.0-30.0 |

| Cooling method | Cooled by wind and water | ||||

| Installed capacity (approx) | KW | 180 | 260 | 340 | 385 |

| Dimensions (L×W×H)(approx) | m | 28x2.6x2.4 | 32x2.8x2.6 | 36x3.0x2.8 | 42x3.5x3.0 |

| Total weigh(approx) | T | 15 | 17 | 20 | 26 |

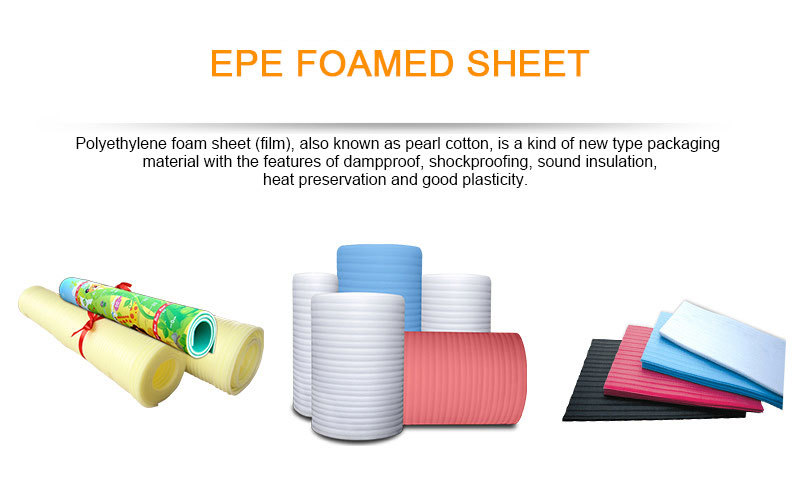

Polyethylene Foamed Sheet/Film, also known as pearl cotton, is a high-performance packing material with exceptional properties such as damp-proofing, shockproofing, sound insulation, heat preservation, and excellent plasticity. It is an ideal replacement for traditional packing materials and is widely used in the packaging of electronic products, household goods, glass, pottery, appliances, furniture, toys, hardware products, and more.

Key Benefits:

◆ Damp-proof, shockproof, and sound insulation

◆ Heat preservation and excellent plasticity for versatile applications

◆ Ideal for protective packaging in various industries, including electronics, appliances, furniture, and toys

Polyethylene foamed sheet/film provides superior protection and is a cost-effective alternative to traditional packing materials, ensuring safe and reliable packaging for a wide range of products.

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.