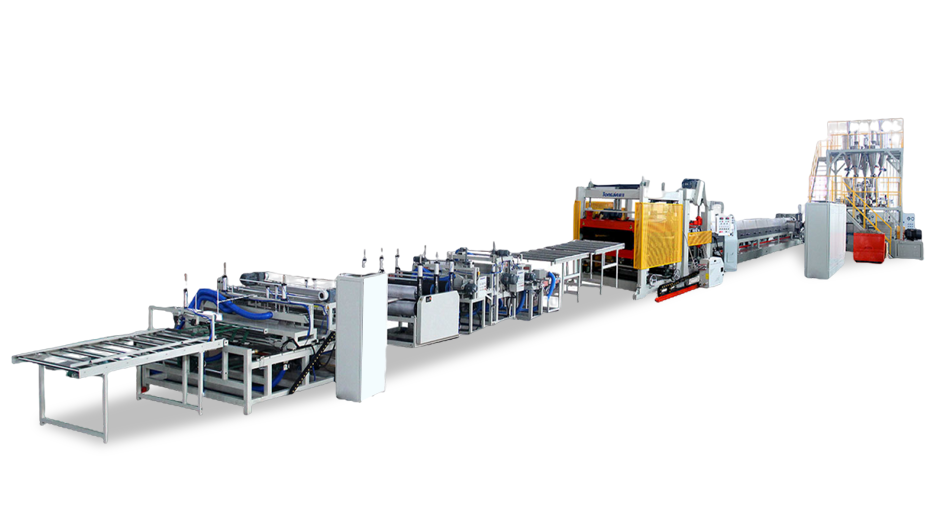

HDPE Large Diameter Plastic Pipe Production Line

- Commodity name: HDPE Large Diameter Plastic Pipe Production Line

Subcategory

Contact information

keyword

Product details

Tongjia's HDPE plastic pipe production line is a highly advanced, patented solution developed in-house. The pipes produced are known for their superior hot melt performance, flexibility, corrosion resistance, lightweight design, and aging resistance. These pipes are the ideal choice for replacing cement pipes, cast iron pipes, steel pipes, and other traditional piping materials. Widely used in municipal water supply, urban gas transportation, and industrial piping applications, Tongjia's HDPE pipes offer long-term reliability and cost-efficiency.

Model | TJ-PEG63 | TJ-PEG250 | TJ-PEG450 | TJ-PEG630 | TJ-PEG800 | TJ-PEG1200 | ||

Extruder |

| Ø65/33, Ø75/33 | Ø75/33 | Ø90/33 | Ø120/33 | Ø150/33 | Ø150/33 | |

Mould |

| single | double | single | single | single | single | single |

Range of pipe dia. | mm | Ø20-Ø63 | Ø75-Ø250 | Ø110-Ø450 | Ø315-Ø630 | Ø450-Ø800 | Ø630-Ø1200 | |

Installed capacity | KW | 75 | 125 | 230 | 380 | 550 | 800 | 1000 |

Dimensions (L×W×H) | m | 28 × 4 × 3 | 40 × 8 × 3 | 52 × 8 × 3.6 | 60 × 10 × 4 | 70 × 10 × 4 | 78 × 11 × 4 | |

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.