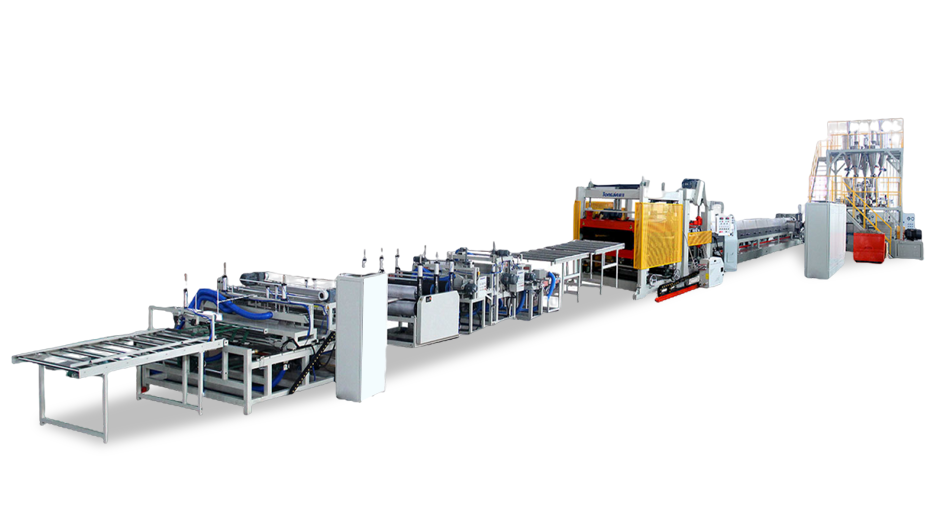

PVC/PE Single/Double Wall Corrugated Pipe Production Line

- Commodity name: PVC/PE Single/Double Wall Corrugated Pipe Production Line

Subcategory

Contact information

keyword

Product details

Mainly using PVC or PE as the main raw material,the line is used to produce single or double wall corrugated pipe. This product has the features of light weight,high corrosion resistance,erosion resistance and cold and not resistance. It is widely used in such fields of communications, electric wire & cable laying and agricultural irrigation,etc.

Single-wall corrugated pipe production line

|

Model |

TJ-DBG90 |

TJ-DBG120 |

|

|

Raw material |

PE |

PE |

|

|

Extruder |

Ф90/25 |

Ф120/25 |

|

|

Range of pip dia |

mm |

Ф65-115 |

Ф115-175 |

|

Water consumption |

L/H |

4000 |

5000 |

|

Water pressure |

Mpa |

0.4-0.6 |

0.4-0.6 |

|

Number of mould block |

Pair |

50 |

60 |

|

Whole length of mould block |

mm |

5180 |

6216 |

|

Move speed of mould block |

m/min |

1-12 |

1-8 |

|

Dimensions(approx) |

m |

18×1.35×1.7 |

21×1.55×2.2 |

|

Total weight(approx) |

t |

6 |

9.5 |

Double-wall corrugated pipe production line

|

Model |

JG-SBG60/125 |

JG-SBG65/132 |

JG-SBG90 |

JG-SBG120 |

|

|

Raw material |

PVC |

PVC |

PE |

PE |

|

|

Extruder |

Ф60/125 |

Ф65/132 |

Ф90/25 |

Ф120/25 |

|

|

Range of pip dia |

mm |

Ф65-110 |

Ф110-165 |

Ф75-110 |

Ф110-160 |

|

Water consumption |

L/H |

5000 |

5500 |

4000 |

5000 |

|

Water pressure |

Mpa |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

|

Number of mould block |

pair |

50 |

60 |

50 |

60 |

|

Whole length of mould block |

mm |

5180 |

6216 |

5180 |

6216 |

|

Move speed of mould block |

m/min |

1-12 |

1-8 |

1-12 |

1-8 |

|

Dimensions(approx) |

m |

20×1.35×2.15 |

24.8×1.6×2.25 |

18×1.35×1.7 |

21×1.55×2.2 |

|

Total weight(approx) |

T |

8.5 |

12 |

6 |

9.5 |

Recommended Product

CONTACT

Service Hotline

Monday to Saturday 8:30-18:00

Shandong Tongjia Machinery Co., Ltd.

Scan the phone site

MESSAGE

Filling in your phone and email information will help us contact you in a timely manner and resolve your concerns as soon as possible.